Arm locking is important to avoid the risk of the articulating lifting arms moving out away from under the vehicle with an inevitable risk of the vehicle falling from the lift.

The risk of arms moving is increased if the rubber grip pads on the end of the arms are worn, damaged or missing.

There has been a history of incidents involving fatalities on 2 post lifts where arms have moved causing vehicles to fall from the ramps.

Action by inspectors:

Where it is evident that Bend Pak / Ranger, Silent Technology or other 2-post lifts using this type of locking device are in operation, visiting staff should make enquiries about the locking mechanism as a matter of evident concern. While these lifts will mostly be found in MVR, they may be installed at other premises where vehicles are lifted, for example at vehicle waste treatment facilities (‘scrap yards’).

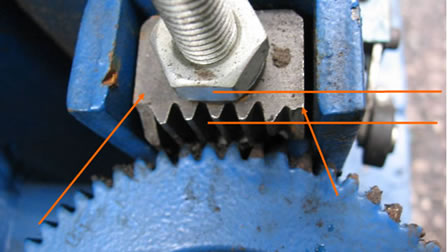

If lifts are discovered where any of the arms fail to lock, the Enforcement Management Model would suggest a possible risk of serious personal injury and a Prohibition Notice should be considered. If the arms lock but no initial or, where appropriate, 6-monthly examination has been undertaken, there is an extreme risk gap when compared to the benchmark of nil or negligible risk (particularly if there is evidence of damage or misalignment in the locking mechanism).

Given that there are established standards, an Improvement Notice (eg under LOLER Reg 9) would be the initial enforcement expectation and prosecution should be considered.

In line with SIM 03/2010/02, old 2-post lifts that lack locking arms should be prohibited from use.

These should now all have been identified and withdrawn from use or otherwise rectified.